The LWT810 Water Jet Loom enhances the productivity and the quality with the latest technology advancements that customers expect from Toyota while achieving the highest energy savings to protect our environment.

High Quality and Improved Productivity

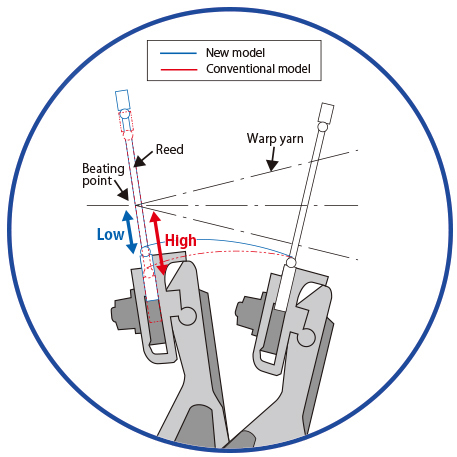

Offering a short stroke and extending weft insertion time has allowed drastic improvements to high-speed operation and enhanced quality while placing minimum strain on the yarn.

Operability and Support

The new function panel offers the latest in electronic technology advancements and troubleshooting including enhanced visibility, improved machine operation functionality, and handling.

Factory Management

New factory management system, based on the Toyota Monitoring System (TMS), offers an increased management level of productivity and quality in real-time by displaying shift reports, actual factory floor layout, and operation status in various formats.

| Negative cam | Crank | Positive cam | Dobby | ||

| Machine Width (W) | 1C (BLD) | R/S+1799 | R/S+1544 | R/S+1544 | R/S+1544 |

| 2C | R/S+2029 | R/S+1774 | R/S+1774 | R/S+1774 | |

| Depth (D) | 1805 | 1805 | 1805 | 1805 | |

| Height (H) | 1966 | 1966 | 2295 | 2332 | |

| (Note 1) The dimensions shown apply to the following specifications: 1. R/S 170 to 280 2. Yarn beam flange diameter: 800 3. Max. roll diameter: 520 (Note 2) Dimensions may differ depending on the required specification. Please contact us final confirmation of size. |

| Item | Standard specifications |

| Drive | Super-fast start-up motor Start, stop, forward / reverse slow motion Activated by push-button operation Solenoid-brake stoppage Automatic compensation for fixed-position stops |

| Beating | Two-sided crank drive with oil bath Multiple short sleysword |

| Let-off | Electronic Let-off Motion Negative-easing double back rollers |

| Take-up | Mechanical take-up motion Flat cloth line |

| Weft Insertion | Flange-type pressurized pump Adjustable ring nozzle Auto pick finder |

| Temple | Lower cover temple |

| Stop Mark Prevention | Selectable main motor start-up Selectable stop / startup angle Adjustable let-off amount Fell forward |

| Selvage | Planetary-gear leno type (enclosed gears) |

| Waste Selvage | Waste selvage on the right with catch cord |

| Water Extraction | Circulating-flow steam-separator type (moisture-removal tank) Energy-saving high-pressure blower |

| Cutter | Mechanical cutter |

| Stop Motion | Leno selvage and waste salvage stop motion IR Feeler LED 4-color signal lamp |

| Lubrication | Oil-bath lubrication method for main parts, grease supply method |

| Main Controls | Large 12-inch interactive touchscreen color function panel 32-bit CPU & function panel Fiber-optic and Ethernet LAN communications network |

| Function Panel | 24-hour / weekly efficiency graphs, beam and cloth prediction, standardized condition automatic set up (CS) Displays individual stop causes Weavers monitor New Weaving Assist System (WAS) |

| Main Options | |

| |

| Item | Variations |

| Designated reed width (R/S) | 170 cm, 190 cm, 210 cm, 230 cm, 280 cm |

| Beating | Super-short stroke ML beating |

| Beating | Positive-easing double back rollers (Front / rear adjustable position) |

| Yarn Beam | Dia. 800 Dia. 914 Dia. 1,000 |

| Temple | Full width temple |

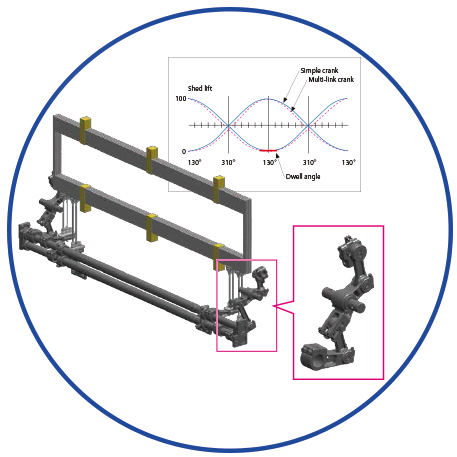

| Shedding | Negative cam (max. capacity 10 frames) Crank (max. capacity 6 frames) Dobby (max. capacity 16 frames) |

| Weft Insertion | Single pump Double pump |

| Length Measurement | BLD measurement Roller feeder with speed control |

Toyota Factory Management System (FACT) 1) For further details and information concerning other combinations of options and variations, please contact Toyota or your Toyota representative. 2) Drawings, data, and photograph which appear in this catalogue are subject to change without prior notice. |

For countries outside the U.S., please click the below link to reach an agent in your area.

https://textile-machinery.toyota-industries.com/

Enhanced beating motion can achieve higher versatility weaving for high-quality textiles.

The larger 12-inch panel provides simple and easy operability with a strong graphical presentation.

Toyota original crank shedding with dwell angle is ideal for weaving densely woven fabrics.