Based on the JAT concept “Weaving the highest quality fabric at the lowest possible cost”, Toyota has embodied the desire to continue developing together with our customers while grasping the needs that change with time. We will continue to contribute to the realization of a sustainable society and the creation of a prosperous future through our air jet looms.

| Item | Standard Equipment |

|---|---|

| Drive |

|

| Beating |

|

| Let-Off |

|

| Take-Up |

|

| Temple |

|

| Weft Insertion |

|

| Selvage |

|

| Waste Selvage |

|

| Stop Motion |

|

| Lubrication |

|

| Main Control |

|

| Function Panel Features |

|

| Others |

|

| Main Options | |

|

|

| Item | Variations |

| Nominal Reed Space (R/S) | 140 cm, 150 cm, 170 cm, 190 cm, 210 cm, 230 cm, 250 cm, 260 cm, 280 cm, 300 cm, 340 cm, 360 cm, 390 cm |

| Let-Off |

|

| Yarn Beam Flange Diameter | 800 mm, 930 mm, 1000 mm, 1100 mm, 1250 mm (pile beam for terry machines) |

| Temple |

|

| Shedding |

|

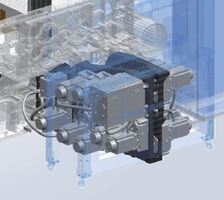

| Weft Insertion |

|

| Stop Motion |

|

| Notes: 1) For further details and information concerning other combinations of options and variations, please contact Toyota or your Toyota representative. 2) Drawings, data, and photographs that appear in this catalog are subject to change without prior notice. |

For countries outside the U.S., please click the below link to reach an agent in your area.

https://textile-machinery.toyota-industries.com/

Toyota introduces the “i-SENSOR” weft insertion system. The world’s first weft sensing technology that detects weft insertion timing as the yarn is passing in REAL TIME. The system then recommends proper adjustments of insertion timings to improve overall loom performance.

Toyota’s original E-shed technology has evolved since its launch in 2000. The 4th generation E-shed model offers further energy savings by optimizing the shedding control movement and introduces a new function that allows customers to weave challenging fabrics at high speed.

The original FACT system has evolved with the JAT910 into “FACT-plus” with improved factory automation functions. FACT-plus supports smooth factory operations by making optimal proposals to machines and operators to reduce downtime and increase productivity.