Toyota Industries Corporation Gains the Highest rating in Survey by CDP

Chosen as an “A List” Company for the “Climate Change” category

[Translation]

Toyota Industries Corporation (President: Akira Onishi) announces that it has been selected as an “A List” company, the highest evaluation possible, in a survey on “Climate Change” category held by CDP*, an international environmental NGO originating in the UK. It was highly evaluated for initiatives including activities to reduce greenhouse gas emissions, alleviate climate change.

With an eye to realizing a prosperous life in harmony with the natural environment by creating a sustainable society, the Toyota Industries Group has formulated the “Seventh Environmental Action Plan,” a five-year plan covering the period from FY2022 through FY2026. It has been engaging in initiatives based on this plan.

We recognize that our selection as an A-list company was based on a comprehensive evaluation of our efforts to respond to climate change, including the initiatives listed below.

- Promoting the environmental impact reduction in product development and production activities by strengthening environmental governance through the establishment of a company-wide environmental management system headed by the President.

- Responding to risks and opportunities related to climate change as one of our CSR material issues, while recognizing that it is an important management issue.

- Disclosing the transparent environmental data, such as greenhouse gas emissions, through third-party verification.

Toyota Industries Group will contribute to creating a sustainable society through global environmental conservation activities while also engaging in combating the key issues of climate change response.

*CDP is an international NGO established in 2000 in the U.K. that aims to promote the reduction of greenhouse gas emissions, water resource conservation and the protection of forests by companies and governments.

In 2022, representing 680 institutional investors (asset scale under management: 130 trillion US dollars) and 280 purchasing corporations (procurement expense: 6.4 trillion US dollars), it conducted a survey and evaluation of major corporations worldwide.

For more information on the Seventh Environmental Action Plan, please refer to the following link

https://www.toyota-industries.com/sustainability/environment/connection/#connection04

Toyota Industries Corporation Releases the New JAT910 Air-Jet Loom

Equipped with Cutting-Edge Technology That Improves Environmental Performance and Supports Efficient Factory Management

Toyota Industries Corporation (President: Akira Onishi; “Toyota Industries”) has remodeled its air-jet loom, a mainstay product of its Textile Machinery Business, for the first time in nine years. The new JAT910 will be on the market from November 28, 2022.

The product is a successor to the previous model, the JAT810, which has been widely used by customers around the world since its release in 2013 and boasts the world’s top market share[1]. Inheriting high-speed/low-vibration technology and superior weaving capabilities, the JAT910 attains further improvements in environmental performance and contributes a more efficient factory management for customers.

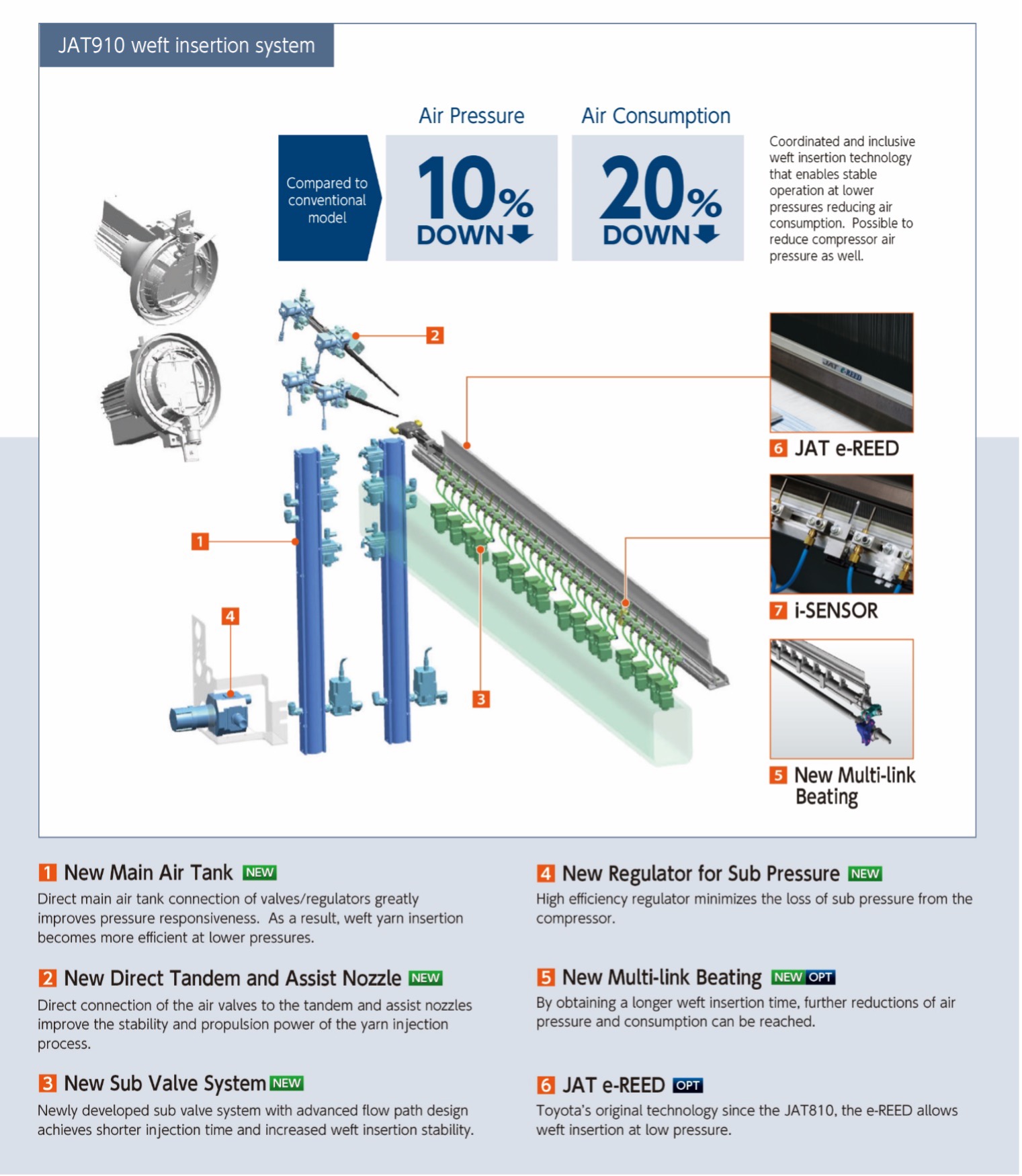

Amid the recent global rise in environmental awareness and soaring energy prices, saving energy is imperative in the textile industry as well. For the JAT910, the mechanism of the air injection system for inserting the weft yarn has been improved. As a result, the air pressure and the air consumption are reduced by 10% and 20%, respectively, compared with the JAT810. In addition, by employing a new main motor and inverter, the new product achieves a 10% reduction[2] in power consumption.

Moreover, the JAT810’s FACT[4] (Toyota FACTory Management System) has garnered high acclaim from numerous customers as they faced the need to reduce operating losses that accompany high-mix, low-volume production. With the JAT910, the functionality has been expanded to include IoT sensor technology attached to the machine that measure numerous items including air pressure and sends optimal pressure settings to a compressor that previously required manual adjustments for each fabric. Another benefit is a feature to give the operator instructions for the next machine to work on. Combined with many other functions, it has evolved into the FACT-Plus that contributes to improving the productivity of the customer’s factory through the use of IoT technology.

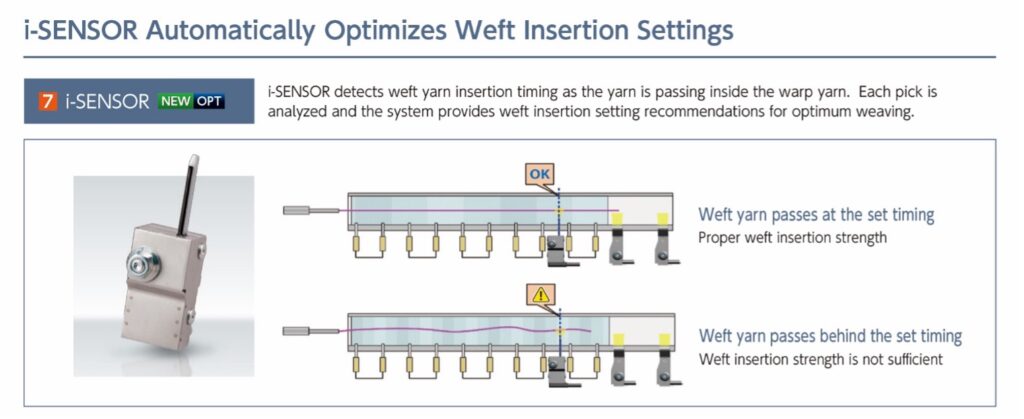

Aside from such improvements, the use of i-SENSOR, the world’s first[3] sensor that detects weft yarn insertion timing as the yarn is passing inside the warp yarn, enables the optimum air pressure and weft insertion requirements to be automatically calculated based on Toyota Industries’ proprietary algorithm, thereby supporting improved efficiency.

For nearly 100 years since founder Sakichi Toyoda completed the Type G automatic loom, Toyota Industries has continued to develop products that meet the needs of the times and responded to customer demand in a wide range of fields, from clothing and home textiles to medical and industrial materials. Through its long-cultivated technological capabilities and global service network, Toyota Industries will contribute to the development of the textile industry by providing products that give consideration to not only the environment but also the workplace.

Information related to the Textile Machinery Business is also available on the following website.

https://textile-machinery.toyota-industries.com/en/index.html

For more details contact:

Toyota Textile Machinery, Inc.

8300 Arrowridge Blvd, Charlotte, NC 28273

Phone: 704.527.5400

1. Survey by Toyota Industries Corporation (Based on actual unit sales)

2. Value under Toyota Industries Corporation’s test conditions with a machine of equivalent specifications

3. Survey by Toyota Industries Corporation

4. A system that collects information on operations, such as the production volume and causes of stoppages of each machine, and supports the customer’s factory management